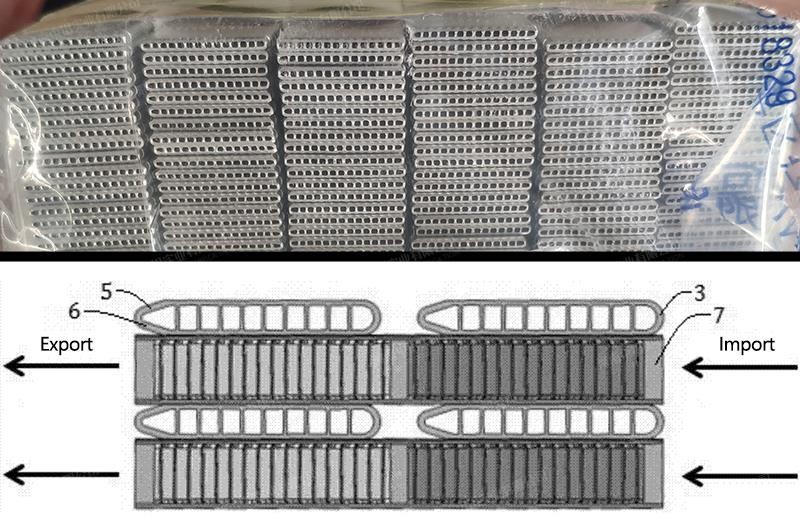

3102 3F03微通道扁管

微通道扁管 是汽车空调全铝制微通道换热器的重要组成部分。它们是承载制冷剂的核心部件。它们通常通过挤出制备。热挤压成型的铝扁管在挤压模具的出口处往往存在弯曲和扭曲问题。因此,铝扁管只有在冷轧和上浆后才能用于微通道换热器的组装,

冷轧施胶中冷轧还原的范围通常为2%~10%。在换热器的装配中,高温退火的过程会导致冷轧铝扁管结构中出现异常大的晶粒,从而导致铝扁管机械性能的下降。通过调整冷轧还原,可以改变退火铝扁管的强度,相应的退火铝扁管具有最低的强度

抑郁症被称为严重抑郁症。例如,3102和3003合金铝扁管的临界下压力分别为4%和6%。

不同合金铝扁管的临界下压力是由合金的加工硬化行为的差异决定的。合金材料的加工硬化行为受溶质原子、晶粒尺寸和二相颗粒等各种结构特性的影响。与3102铝合金相比,3f03合金含有更高浓度的Mn元素,具有优异的耐腐蚀性

除了耐腐蚀性外,还发现增加铝合金中Mn的含量有利于通过固溶强化来提高合金的强度。目前,关于3f03铝扁管的显微组织表征和加工硬化行为的研究很少,因此无法比较3102合金和3f03合金之间加工硬化行为的差异。金属在冷轧和退火过程中的微观结构演变是工业生产中不断受到关注的关键问题之一。研究发现,冷轧变形后,合金中以位错的形式在结构中存在残余应变。晶粒结构中残留的位错结构决定了晶粒结构在后续退火过程中的演化行为。由于加工硬化行为不同,在相同条件下的冷轧/退火过程中,两种合金中会出现不同的晶粒结构特性。

- (1) 3102微通道扁管3102的平均 晶粒长短轴比为1 5~1。在6的范围内,3f03挤压铝扁管的平均晶粒尺寸较大。5%冷轧后,3102铝扁管增强的晶粒结构具有较高的加工硬化度。在600°C / 3 min下退火后,两个合金铝扁管的微观结构中出现异常的大颗粒。

- (2)具有应变强化校正项的本构模型可以精确计算出3xxx铝扁管材料的应力-应变曲线,并且可以求解单向张力过程中位错密度和位错的平均自由程演变。

- (3) 3102微通道扁管 在塑性变形过程中具有较高的Si固溶体浓度和更小的晶粒尺寸,较低的位错平均自由程和较高的加工硬化率。与3f03挤压铝扁管相比,3102挤压铝扁管具有较低的临界下压力。